Hull of innovative LNG bunker tanker under construction at Marine Projects

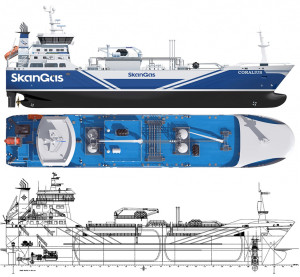

Fig.: SkanGas

Gdansk-based Marine Projects is involved in what is probably the most interesting and innovative vessel with a hull subcontracted and currently under construction in Poland, namely, the LNG bunker vessel Coralius.

Swedish energy distributor Skangas announced that it will make LNG (Liquefied Natural Gas) more readily available as marine fuel in the area Skagerrak, Kattegat and Baltic Sea by operating the Coralius, a new specialised bunker vessel. The vessel will offer greater flexibility by operating both as a ship-to-ship bunker vessel, as well as a feeder. The new bunker vessel will be ready in 2017. Skangas will take the 5800 m3 capacity bunker vessel Coralius on a long-term charter. The vessel will be owned by the Swedish/Dutch joint venture Sirius Veder Gas AB and operated by Sirius Rederi AB of Sweden.

The partially outfitted hull is under construction in Poland and is expected for delivery from Marine Projects yards in October or November 2016. The final hull outfitting and turn-key delivery of the vessel to owners and operators will be done by Royal Bodewes in the Netherlands.

The partially outfitted hull is under construction in Poland and is expected for delivery from Marine Projects yards in October or November 2016. The final hull outfitting and turn-key delivery of the vessel to owners and operators will be done by Royal Bodewes in the Netherlands.

The bi-lobe LNG cargo tanks were ordered in 2015 from TGE Gmbh. Once completed, the tanks had been transported to Gdansk in mid-August 2016, onboard a heavy-lift vessel Annette, unloaded onto a pontoon – barge and towed to the quay being used by Marine Project. The tanks will be fitted into the vessel in Poland.

The steel cutting and the assembling of the hull sections started at Marine Projects Ltd. in November 30, 2015 and on the 11th of December 2015 the keel-laying was carried out in the presence of Classification Society Bureau Veritas.

The newbuilding Coralius is designed to fulfill the requirement of a fully IGC classified vessel, but the design also takes into account expected future standards, as well as charterers’ requirements. The vessel is designed for both efficient short sea trading and STS LNG bunkering operations for all types of vessels, both in- and offshore.

The newbuilding Coralius is designed to fulfill the requirement of a fully IGC classified vessel, but the design also takes into account expected future standards, as well as charterers’ requirements. The vessel is designed for both efficient short sea trading and STS LNG bunkering operations for all types of vessels, both in- and offshore.

The cargo system is based on two LNG tanks of bi-lobe type designed for 4,5 bar(g), with a total volume of 5800 m3, two compressors and four cargo pumps. The capacity of the cargo pumps will be 4 × 250 m3/h and the cargo compressors will have a capacity of 2 × 532 m3/h. The loading/discharge capacity will be abt 1000 m3/h. Redundant configuration of Nitrogen generators will be installed. The cargo operations will be done without any release of methane, because of the boiler suitable burning mixture of methane and nitrogen. With this boiler, the methane slip is zero and that is an important factor in the environmental performance of the vessel.

The manifolds will be located at two positions in the length of the vessel, this in order to achieve the best flexibility for receiving vessel or terminal. The cargo automation system is supplied by Siemens Automation.

In combination with the hull design of very low block coefficient, the emissions will be extremely low related to traditional vessels. Coralius will be equipped with one bow thruster of combination type, also suitable as alternative propulsion of the vessel, and one stern thruster. All to receive high redundancy and reliability.

Photo: Piotr B. Stareńczak

Cooling water waste heat from all installed engines will be transferred to the vessels heat consumers, to further reduce of the emissions. biodegradable oil will be used for the stern tube arrangement.

Comfort class will be used to receive high standards for the crew onboard. The company’s philosophy is that high retention rate is important to build up the best knowledge and experience onboard to achieve the absolute best performance of the vessel.

Fender arrangement have been developed so that no heavy lifting is required, two cranes on deck, fender-cradle arrangements, ensures a work-friendly handling of the equipment required for bunkering.

The vessel Coralius is being built in the Joint industry project (JIP) Flexi as one of the activities in the umbrella project Pilot LNG. The activity is co-funded by EU under TEN-T and part of the Zero Vision Tool platform. The objective of the activity to develop the LNG bunkering infrastructure by offering a LNG bunkering possibility in the Skagerrak/Kattegat area.

Coralius – principal particulars:

- ship type – LNG gas carrier IGC type 2G -165°C, 500 kg/m3, ice class Finnish/Swedish Ice Class 1A;

- length over all 99.60 m,

- length between perpendiculars 90.00 m,

- breadth moulded 17.81 m,

- breadth extreme 17.95 m,

- depth moulded to main deck 10.00 m,

- design draught 5.70 m,

- scantling draught 5.90 m,

- deadweight 3000 t (4000 t according to other sources),

- cargo capacity 5800 m3;

- propulsion: main engine Wärtsilä 6L34DF – 3000 kW, main gearbox and CPP Wärtsilä; speed 13.5 knots; aux engines LNG 2 × 375 kW, aux engines diesel 1 × 475 kW; steering gear Roll Royce 2 × 70 degree, rudder Becker, twisted full spade type, bow thurster azimuth / tunnel, ZF – 600 kW stern thruster tunnel, Verhaar Omega – 400 kW.

PBS, rel (SkanGas)

Below: a video showing the unloading of the tanks destined for the Coralius.