Fully equipped ship from Szczecin for CIG and ABIS Shipping nears completion

In Szczecin the multi-purpose havy-lift vessel is nearing completion in joint effort of Polish and foreign companies. The ship was contracted with Central Industry Group (CIG) by ABIS Shipping, both of the Netherlands. CIG, in turn, subcontracted the construction of partially outfitted hull to Partner shipyard (Partner Stocznia Sp. z o.o.).

The open top heavy-lift multipurpose vessel, ABIS Esbjerg, is being currently outfitted at the quay of former Szczecin Shipyard. The outfitting works are performed by a number of Polish and foreign companies, including Szczecin based K.G. Konstrukcje Ltd. and Breman Shipping Installation from the Netherlands, responsible for HVAC, hot and cold water and sanitary systems. Partner shipyard delivered hull with some of the piping and painting works done.

Szczecin based companies, mainly Partner shipyard, have been co-operating with Central Industry Group and Shipkits B.V. for quite a time, supplying Dutch companies with partly outfitted ships or ship blocks and sections. ABIS Esbjerg, however, will be the first ship to be outfitted and turn-key delivered entirely in Poland.

ABIS Esbjerg is expected to be delivered in Szczecin in June this year.

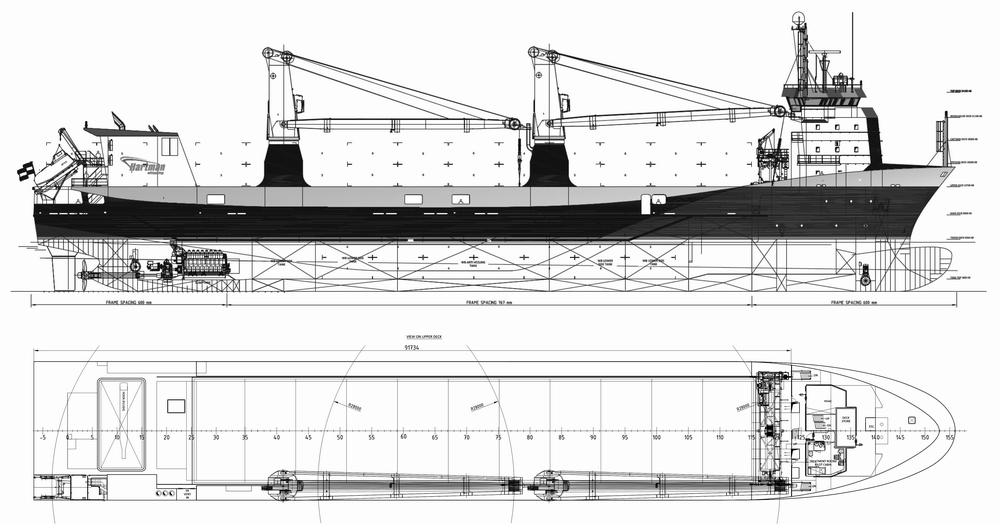

The ship, newbuilding no. 123, is the fifth unit from the series represented by existing Arctic Dawn, Indian Dawn, ABIS Dusavik and ABIS Dunkerque, with partially outfitted hulls also coming from Poland. This is the “E”-series in Owners’ nomenclature or CIG HLV 4400 type in main contractor – Central Industry Group – designation.

The HLV 4400 or the “E”-series ship is designed to sail as an open top vessel with the accommodation and wheelhouse situated on the forecastle deck to be able to sail with large and oversized cargo exceeding ship length or height, with one box shaped cargo hold for the transportation of special cargo and voluminous goods, as well as 20’ and 40’ containers (so high cargo is possible without obstructing line of sight).

With the heavy lift cranes the ship is capable of self load / discharge – lifting 270 tons loads at once using the special made ballast pontoon and anti heeling system (with 2 x 150 tons cranes used in tandem).

This ship is able to reach more ports then standard heavy lift ships can do. With the relative high speed (up to 17-18 knots) this ship will have a larger pre sailing range and can deliver the loads in shorter times than most other heavy lift vessels can do. The vessel features flush cargo deck and movable pontoon tweendecks with 3 loading positions (lowest is on step in hold).

The ship is prepared for exhaust scrubber installation in the funnel and prepared for water ballast treatment unit in pumproom (fore ship).